1. Types of containers

In fact, containers are classified into many types based on different standards such as according to size, according to container packing materials, according to use, ... However, most people today when it comes to classifying containers, people will talk about a few. Popular types as below:

DC (Dry container): is a dry container, also known as a normal container

HC (High cube): is a tall container

RE (Reefer): is a refrigerated container

HR (Hi-cube reefer): is a refrigerated, tall container

OT (Open top): is a container that can open the roof

FR (Flat rack): is a container that can be opened and closed

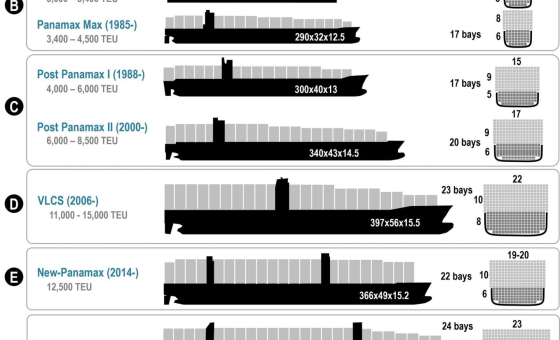

Container capacity is calculated in TEU (twenty-foot equivalent units) – A unit equivalent to 20 feet (1 foot = 0.3048 m). Therefore, people often call a 20-foot container 1 TEU. For this reason, the 40 foot ~ 2 TEU, 45 foot container variants are also considered as 2 TEU.

1.1 DC (Dry container)

Dry container is abbreviated as 20'DC or 40'DC. This is the most basic type, representing the unit of measure TEU. This type is often used to close dry goods, heavy in nature, requiring little volume (eg rice, flour, steel, cement, ...).

1.2 HC (High cube)

The outstanding feature with this type of container is its terrible cargo capacity. In particular, in addition to being used to pack goods with large sizes and volumes, there is another option we can use this container as an office container or a house container.

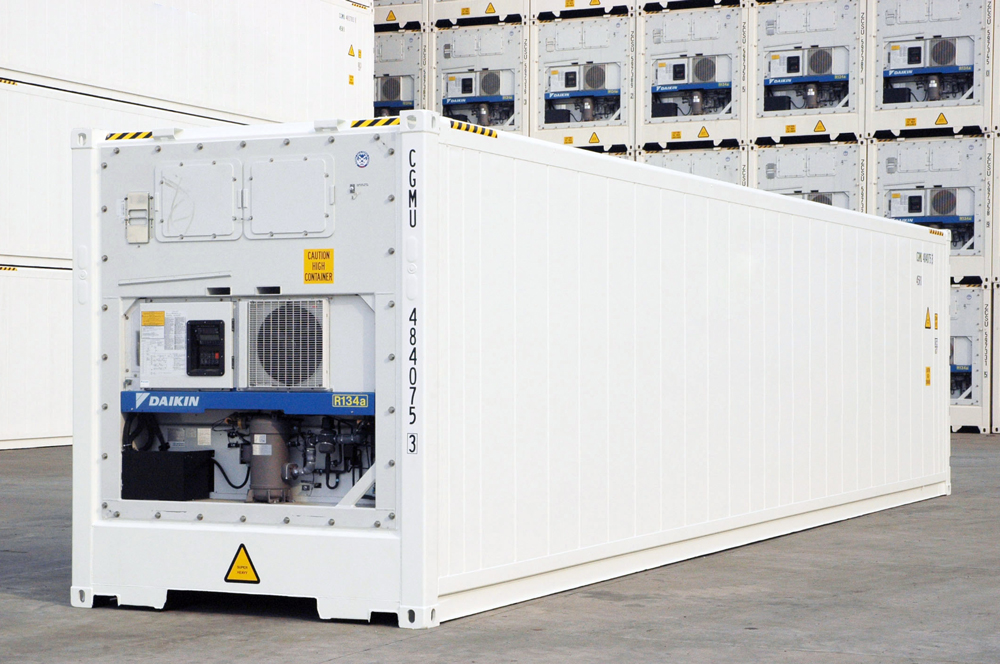

1.3 RE (Reefer)

Refrigerated containers are designed for cold storage, refrigerated trucks transporting goods that require temperature and humidity control to be suitable for that type of goods. Refrigerated containers are usually of two types, aluminum refrigerated containers and iron refrigerated containers. Due to extreme temperature conditions inside the container, the inner layer of the refrigerated container is made of stainless steel. With these types of containers, storage costs will be very expensive.

1.4 HR (Hi-cube reefer)

Refrigerated and tall containers are similar to refrigerated containers, but they are containers for transporting goods with special requirements for large capacity.

1.5 OT (Open top)

The open-top container is designed to be convenient for loading and unloading goods through the top of the container. After packing, the roof of the container will be covered with canvas to prevent rain and wind from affecting the goods. This type of container is used to transport machinery and equipment.

1.6 FR (Flat rack)

The container is designed with no walls, no roof, but only the floor is a solid ground, specialized for transporting heavy goods such as machinery, equipment, iron and steel, etc. The ground container has a double-walled type (front face). and back), this wall can be fixed, folded down, or removable.

2. Seal container

Container seal is a container lead clamp, also known as a container sealing lock, used to seal the container before exporting goods to foreign countries in order to ensure that the goods inside the container are full in quantity and limit the impact on the environment. quality.

On these lead clamps are shown symbols right on the lead surfaces. The lead clips will seal the goods and will come off on their own when the container door is opened. The carrier will be the party to ensure that the goods arrive at the port of destination with the lead clamp intact. Each of these seals has a serial number called a Seal number consisting of 6 digits, depending on the number of uses, zeros will be added first to make up 6 digits. Each container will be sealed with a unique lead number, unlike any other, to ensure the container is not replaced with another seal. If there is a change, ie the goods have changed, the importer has the right to refuse to receive the goods, and to hold the carrier responsible. After the shipper packs the goods into the container and clamps the lead, this seal number will be declared on the documents so that the parties can understand such as: P/L, B/L, C/O.

3. Container size

Containers come in many types, and the specific size of each type can vary more or less depending on the manufacturer. However, due to the need for standardization so that it can be used on a global scale, sizes and loads are often applied according to ISO standards (ISO 668:1995(E)). Accordingly, the current container sizes have 3 types: 20' (feet), 40' and 45" containers. Here are the tare dimensions of these 3 types of containers:

- Container 20 feet: 6,060m long; 2,440m wide; 2,590m . high

- Container 40 feet: 12,190m long; 2,440m wide; 2,590m . high

- Container 45 feet: 13.716m long; 2,500m wide; 2,896m . high

.png)

.png)

.png)

.png)

.png)

However, this is only the outer size, before packing the goods into the container, we should refer to all the specifications in detail including: outside size (covered), inside size (inner), dimension width, height of the container door, cargo load, ... to choose the appropriate type of container.

4. Symbols on the container

We see on the container shell there are many types of signs and codes expressing different meanings. They are inscribed on the front, rear, inside, outside, and even on the roof; maybe only under the bottom there are no symbols.

The current standard for container markings is ISO 6346:1995. Accordingly, these marks are divided into the following main categories:

-Identification system

-Size and type codes

-Operational markings

4.1 Recognition system

The container recognition system consists of 4 components:

-Owner code

-Equipment category identifier / product group code

-Serial number (serial number / registration number)

-Check digit

- Owner code: The owner code (also known as the container prefix) consists of 3 uppercase letters that are agreed and registered with the international registry through the national registry. or register directly with the Bureau of International Containers - BIC (Bureau International des Containers et du Transport Intermodal).

After registration, the ownership of this code is officially recognized worldwide. A firm can own one or more different codes, although the BIC restricts this, and imposes certain conditions on the registration of multiple codes.

- Equipment category identifier / product group code: is one of the three capital letters below, corresponding to a type of device:

U: freight container (freight container)

J: detachable freight container-related equipment

Z: tractor (trailer) or trailer (chassis)

The use of any letter other than the above three (U; J; Z) as the device type designation is considered non-compliant with ISO 6346.

- Serial number / registration number: this is the container number, consisting of 6 digits. If the serial number is not 6 digits, zeros are added in front to make it 6 digits. For example, if the serial number is 1234, then 2 extra zeros will be added, and the full serial number will be 001234. This serial number is set by the container owner himself, but following the principle of every The number can only be used for one container.

- Check digit: this number is generated by summing the letters and numbers converted from the previous 10 letters and numbers and then dividing by 11, the remainder is the check digit. Currently there is software to convert and calculate the check digit, but it is still possible to calculate it manually and will continue to study how to calculate this check digit.

The use of a check number is to minimize the risk of errors during the entry of the container number. The fact is that the number of containers is used by many objects (shippers, forwarders, shipping lines, customs ...), on many documents (B/L, Manifest, D/O...), so the possibility of entering the wrong number is very big. Each container number (including prefix and serial number) corresponds to a check digit. Therefore, incorrect input will mostly be detected because the check digit is different from the actual one. However, it should be noted that this is not absolute, because if it is wrong by 2 or more characters, the check digit is still correct, and the error is not detected.

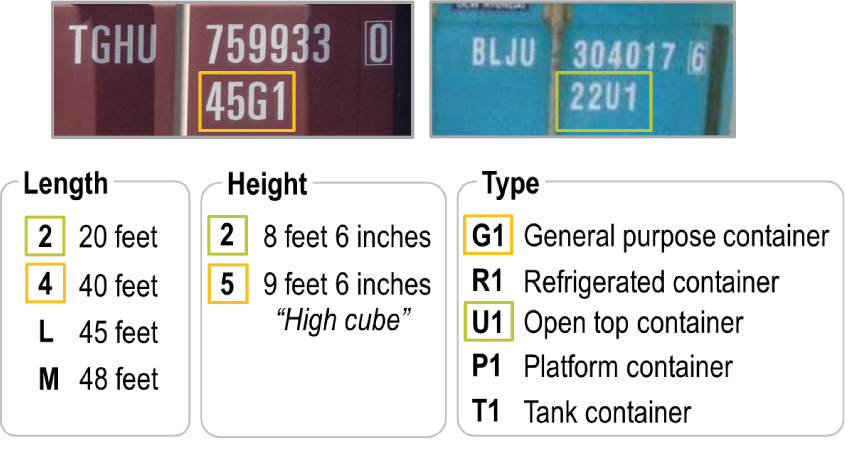

4.2 Size and type code

- Size code: 2 characters (letters or numbers). The first letter indicates the length of the container: Number 2 means length 20ft, number 4 means length 40ft, letter L means length 45ft. As in the image above the digit 4 represents this container's length is 40ft (12,192m). The second character represents the container height: the number 0 represents 8ft, the number 2 represents 8ft 6in, the number 5 represents 9ft 6in. As in the photo above the digit 2 indicates a container height of 8ft 6in (2,591m).

- Type code: 2 characters. The first character indicates the container type. Some common container type symbols such as: G-General (Regular Container); R-Refrigerate (Refrigerated Container); U-Open top (Container open roof); … In the above example: G stands for this type of normal container. The second character denotes the main feature related to the container, the number 1 (after the letter G as shown in the picture) means the container has an upper ventilation opening. Usually this symbol we do not need to pay too much attention when checking the receiving container

In a nutshell, 42G1 in the picture above shows this as a regular container, 40ft long, 8ft 6in high, top vent.

4.3 Operational markings

Mining symbols are of two types: mandatory and optional.

Mandatory symbols include container load, electrical hazard warning; tall containers.

The maximum gross mass (maximum gross mass) is indicated on the container door. Some containers also show tare weight or allowable payload.

Warning sign of electric danger from the upper power line, used for all containers with ladders installed.

Containers over 2.6 meters tall: required for containers over 8ft 6in (2.6m). For example, the figure below shows a 9ft 6in (2.9m) high container.

Optional markers: maximum net mass, country code

Maximum net mass (max net mass) affixed to the container door, below the maximum container weight mark.

Country Code (Country Code) consists of 2 letters that represent the name of the country that owns the container. In the image below, US stands for United Stated (USA).

In addition to the three main types of symbols presented above, on the container shell there are also signs describing other necessary information such as:

Safety certification plate CSC

Sea of acceptance of customs

The symbol of the international railway organization UIC

Registrar's logo

Test plate (of the registry), stacking height

Brand name (Maersk, MSC...), logo, slogan (if any)

Manufacturer's mark (CIMC, VTC...)

Notes on materials for making container walls (corten steel), repair instructions (…repaired only with corten steel)

Material table for manufacturing container parts; Notes, …

Information on wood treatment (flooring)

Dangerous goods label (if any)