Containers are an essential item in freight transport. However, many people still do not understand the rules and techniques of container packing, so…

Container is "hard packaging" used to transport goods. Containers have the following characteristics: sustainability and sufficient strength to be suitable for reuse.

Containers designed to be able to carry goods by one or more modes of transport without having to be unloaded and repacked along the way; Equipped with equipment that allows the vehicle to be loaded and unloaded, especially when transferring from one mode of transport to another. And it's designed for easy loading or unloading of containers.

So how do we need to know the techniques of container packing?

1. Determining the source of goods suitable for the container:

+ Group 1: All kinds of goods completely suitable for transportation by container.

Including: Dry grocery, canned food, leather products, plastic or rubber; household appliances, silk, fabrics, metal products, toys, furniture, etc.

Goods carried in dry containers; Ventilated containers or insulated containers, etc. Depending on the specific requirements of the characteristics of the goods.

+ Group 2: Goods suitable for carriage by container:

Including: Coal, ore, kaolin, etc. These are commodities with low value and large volume of trade. These goods in terms of nature as well as technology are completely suitable for transportation by containers. But in terms of economic efficiency, it is not appropriate (the ratio between the freight and the value of the goods).

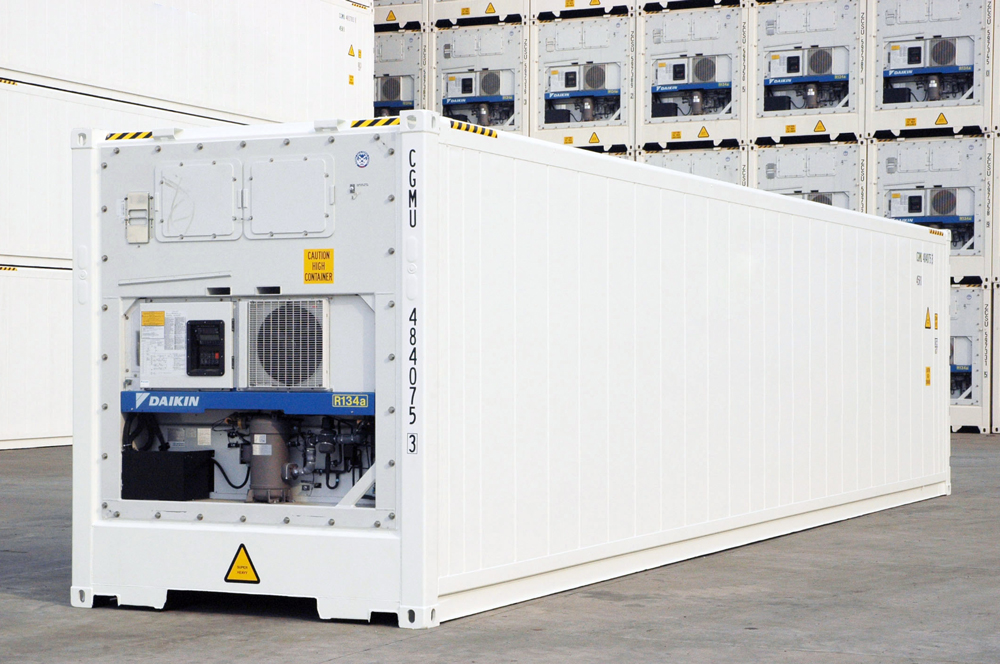

+ Group 3: These goods have special physical and chemical properties such as: perishable goods, frozen goods, live animals, super-heavy goods, dangerous and toxic goods, etc. These goods must be packed with plastic. Specialized containers: insulated containers, ventilated containers, flat containers, animal containers, etc.

+ Group 4: Goods suitable for transportation by container: boxed iron, scrap, rolled iron, super-long, super-heavy goods, heavy trucks, radioactive substances, etc.

2. Identify and check the types of containers when using:

The inspection should be carried out as soon as the shipping operator delivers the container. When detecting containers that do not meet the prescribed technical standards, they must immediately notify the transport operator. (Container dispatcher). Absolutely do not accept, complete request; change to another container.

If the container inspection is not thorough. During transportation if any damage occurs due to the defect of the container. The shipper must bear all losses incurred.

Test content includes:

– Check the outside of the container.

Observe and detect scratches, damage, cracks, holes, deformation due to impact, etc. Must check the roof, the assembled roofs of the container. This is an area that is often overlooked during inspection, but it is a critical structure of the container with regard to shipping safety.

– Check inside the container.

Check the watertightness by observing the light rays passing through to detect holes or cracks from inside the container. Check the studs for damage or protrusion. Check covers or other equipment such as ventilation holes, cold air ducts, etc.

– Check the container door.

The operating situation when opening and closing the door and locking the door seal, ensuring the safe opening and closing, sealing firmly and tightly to prevent water from entering.

– Check container hygiene status.

Containers must be cleaned well, dry, free from odors or dirty wires.

Goods after being packed into containers do not meet hygiene standards. It will cause damage to the goods and at the same time be easily detected by the health agency of the sending country => causing difficulties.

– Check the specifications of the container.

The specifications of the container are written on the shell or on the safety certificate. Container specifications include:

+ Maximum weight or gross tonnage of the container (Maximum Gross Weight). when the container is full of goods to the allowable safe limit. It includes the maximum allowable weight plus the container weight.

+ Net tonnage of the container (Maximum Payload): The maximum weight of goods allowed in the container. It includes: weight of goods, packaging, pallets, materials used for dunnage, supporting goods in the container.

+ The weight of the container (Tare Weight) depends on the material used to make the container.

+ Container capacity (Container internal capacity) means the maximum cargo capacity of the container.

3. Comply with technical requirements for container packing.

4. Evenly distribute the weight of the cargo on the container floor

The purpose of evenly distributing the weight of the cargo on the floor of the container is to avoid the weight being concentrated in one point or place on the floor. The beams at that site are subjected to excessive loads and thus may crack or warp.

To avoid the above risks, it is necessary to have an accurate and specific understanding of the situation of the goods and weight, packaging and physical and chemical characteristics to decide the appropriate distribution.

The center of gravity of the container and the cargo must be kept from being deflected. The container will lose balance during loading and unloading, which may cause the container to slide sideways; overturn or fall.

When the cargo is a machine with a complex shape that is difficult to determine the center of gravity, an appropriate rack should be made; There are padding and ligatures to fix the position.

When loading more than one type of cargo in one container, the load must be loaded below; light cargo on top and, if necessary, place extra padding and tie carefully.

a. Lining in containers:

Cargo liner is an indispensable action in loading and unloading in order to avoid the collision of goods, causing damage to each other and damage to the container. Good liners not only ensure safety, but also facilitate stacking on top of each other. (especially for fragile or circular goods) adds economic benefits.

Lining materials must ensure hygiene, do not create an environment for harmful insects to multiply. And it is also important to pay attention to whether the importing country has regulations on the use of backing materials.

b. Reinforcing goods in containers:

Cargo reinforcement is a common measure applied to fill gaps between packages; between the cargo and the wall to prevent the goods from moving; collision during transportation, loading and unloading. There are many ways to reinforce goods: using wooden pillars to support using wooden racks, wedge pins, pads; or use ropes, chains, straps or nets to secure.

It is necessary to reinforce the cargo firmly and firmly, but it should not be tied too tightly, increasing great pressure on the weak fulcrums of the container. Such as: door, front wall; Columns or racks should be arranged vertically on the container.

c. Limit and relieve pressure or tremors:

During transportation and loading and unloading, collisions cannot be completely eliminated. But it is possible to use an object that has a limited effect and relieves pressure or shock. These are usually flexible, elastic materials such as foam; cotton mattress, plastic bag containing air, …

d. Preventing goods from being hot and steaming:

Because the goods are packed in closed containers, there is no condition to check the temperature and humidity inside. Steaming occurs on the inner surface of the container and the metal cargo surface. This is a place exposed to and affected by the external climate. When the outside temperature rises, the inside temperature is lower than the dew point of the air => the excess water vapor will condense into drops. Causes steaming.